Before

There were difficulties in handling various silica powders in the customer’s equipment due to the fine particle size and diversified powder flowability (fluidity). For instance, some silica powders were easily flushed(*1) and the other ones were sometimes adhered to the surface of machine parts. Our customer put importance not only on the stability in constant feeding but also on the adaptability for both tricky powders to switch their production line.

After

Stabilized constant feeding process is achieved for the two types of silica powders with different characteristics. Through this procedure, customer can readily switch their production line. Detachable/exchangeable special attachments were applied for the flushing powder and sticky powder.

Our Proposal

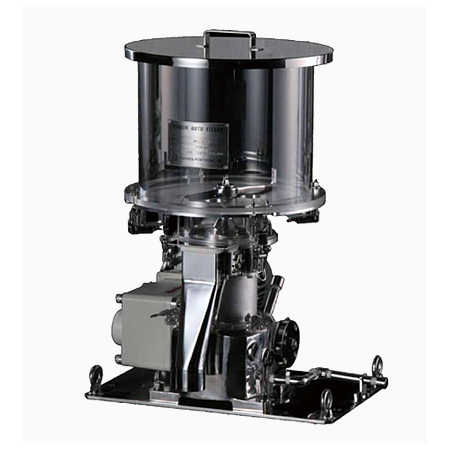

Funken proposed FUNKEN AUTO FEEDER (FSR type) for the flushing powder and FUNKEN AUTO FEEDER (FS type) for sticky powder. The customer can exchange the rotor and some other parts from FSR type to FS type to switch their production line because the other parts have exactly similar dimensions.

*For switching of powder batches, we also have FUNKEN CARTRIDGE FEEDER.

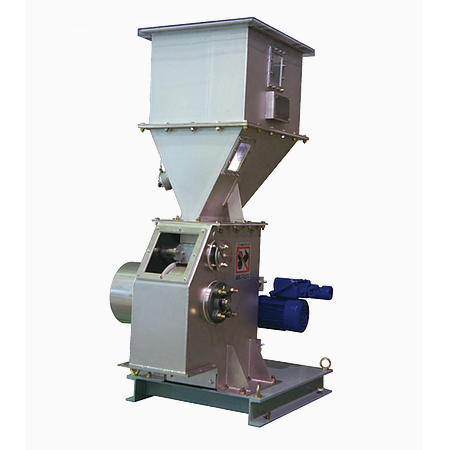

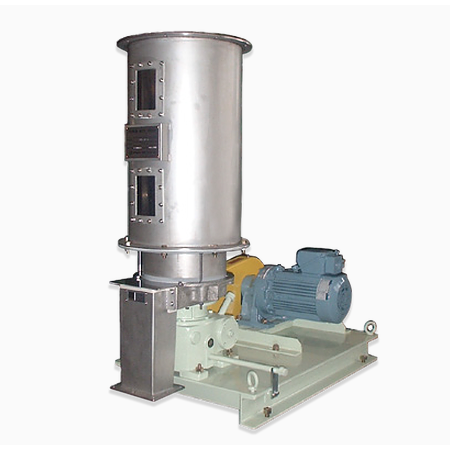

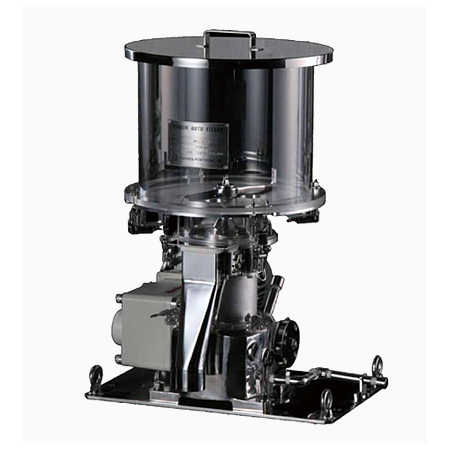

FUNKEN AUTO FEEDER (FS type)

FUNKEN AUTO FEEDER (FS type)

The first and basic type of machines is a FUNKEN AUTO FEEDER. It is a very reliable feeder for general powder as well as cohesive and strongly adhesive powders. The highly accurate feed rate is within +0.5 to 1.0% in volume for feeding rate ranging from 0.5 L/h to 100 m3.

Product details

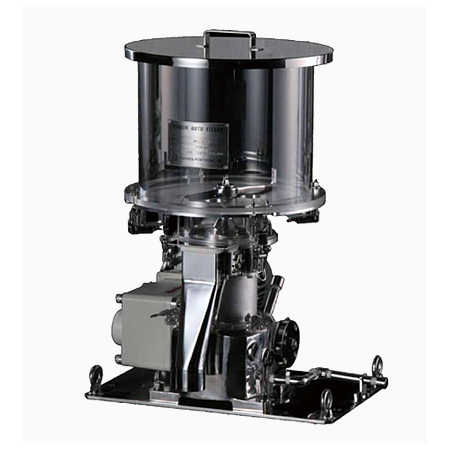

FUNKEN CARTRIDGE FEEDER

FUNKEN CARTRIDGE FEEDER

The cartridge Feeder is designed on the basis of FS type Funken Auto Feeder and assures you stable and constant feeding/dosing. At the same time, You can disassemble the machine quickly without any tools. The feeding parts of the machine are made as cartridges and are easy to change with spare parts.

Product details

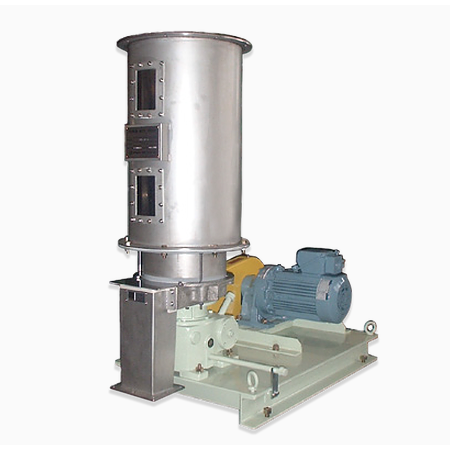

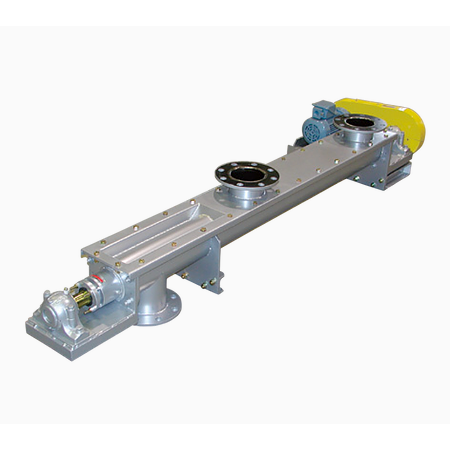

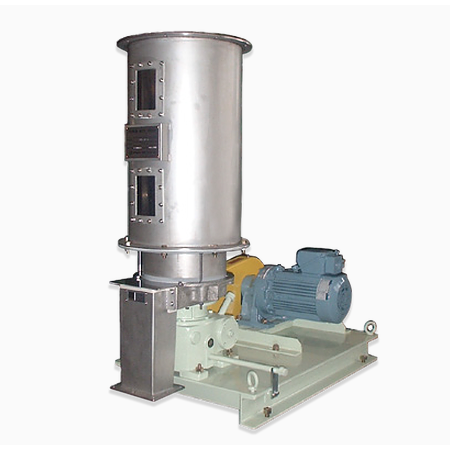

FUNKEN ROLL FEEDER

FUNKEN ROLL FEEDER WEIGHING AUTO FEEDER

WEIGHING AUTO FEEDER FUNKEN FLOW MIXER

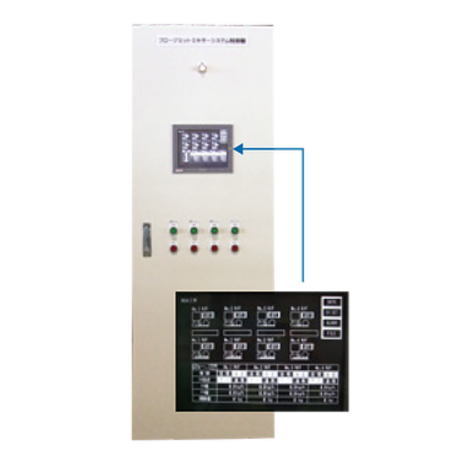

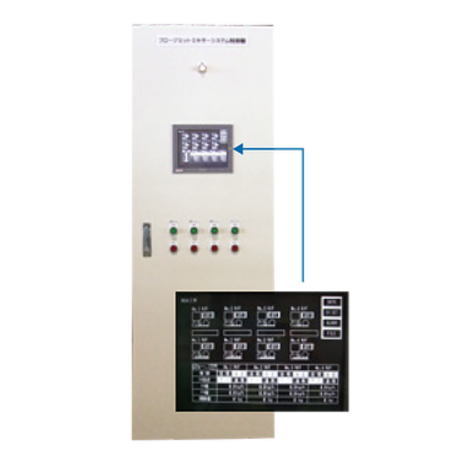

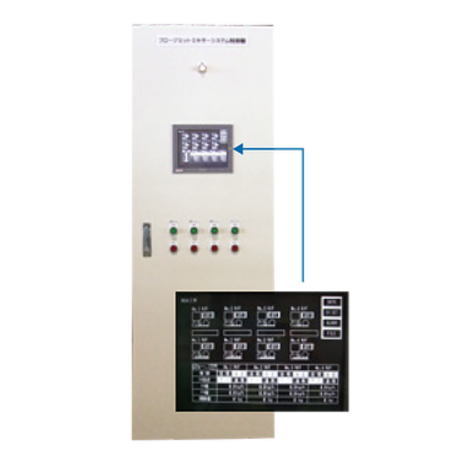

FUNKEN FLOW MIXER FUNKEN CONTROL PANEL

FUNKEN CONTROL PANEL

FUNKEN AUTO FEEDER (FS type)

FUNKEN AUTO FEEDER (FS type) FUNKEN CARTRIDGE FEEDER

FUNKEN CARTRIDGE FEEDER

FUNKEN AUTO FEEDER (FS type)

FUNKEN AUTO FEEDER (FS type) FLOW JET MIXER

FLOW JET MIXER FUNKEN CONTROL PANEL

FUNKEN CONTROL PANEL

FUNKEN WAP FEEDER

FUNKEN WAP FEEDER FUNKEN CONTROL PANEL

FUNKEN CONTROL PANEL

FUNKEN CARTRIDGE FEEDER

FUNKEN CARTRIDGE FEEDER