Volumetric feeders are basic design feeders for a variety of powders, from commonly used powders to adhesive or cohesive powders. They are extremely reliable machines to realize high accuracy and precision feeding. We have various original products depending on the physics of powder, feeding rate, and required specifications.

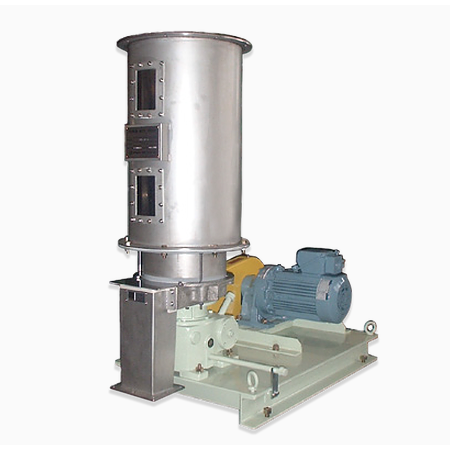

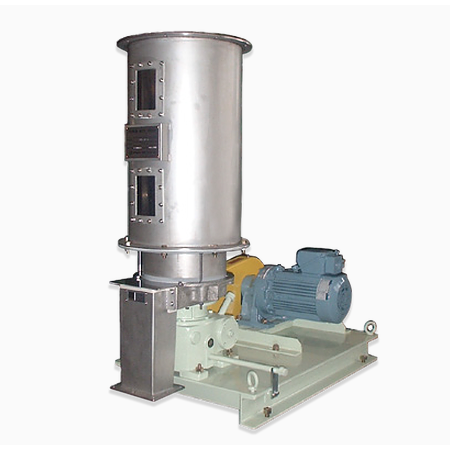

FUNKEN AUTO FEEDER (FS model)

For general powders

The FS model is a very reliable feeder for general powder as well as cohesive and strongly adhesive powders. The highly accurate feed rate is within +0.5 to 1.0% in volume for feeding rate ranging from 0.5 L/h to 100 m3.

DOWNLOAD

CATALOGUE

Product features

-There is no bridging or blocking during feeding due to the unique agitating mechanism of the feeder.

-The inside powder pressure is kept constant due to the pressure-adjusting structure of the feeder regardless of the level of powder. This makes the feeding rate stable.

-High accuracy and precision feeding is achieved based on the discharging mechanism from the step disc.

Industries

| Petrochemical |

Chemistry |

Foods |

Civil |

Laboratory |

Environment |

Others |

| ○ |

○ |

○ |

○ |

○ |

○ |

○ |

Model/Capacity

| Model |

Maximum capacity (Lit/h) |

Power (kW) |

| S |

50 |

0.2 |

| J |

300 |

0.4 |

| Q |

900 |

0.75 |

| E |

3,000 |

1.5 |

| K |

6,000 |

2.2 |

| R |

20,000 |

3.7 |

| M |

50,000 |

5.5 |

| U |

100,000 |

7.5 |

*Capacity and ratio can differ based on the physics of powder.

*1 Feeding rate accuracy in variation -less than ±0.5-1.0% ( for constant apparent bulk density)

*2 Capacity range is from 1 to 10-20.

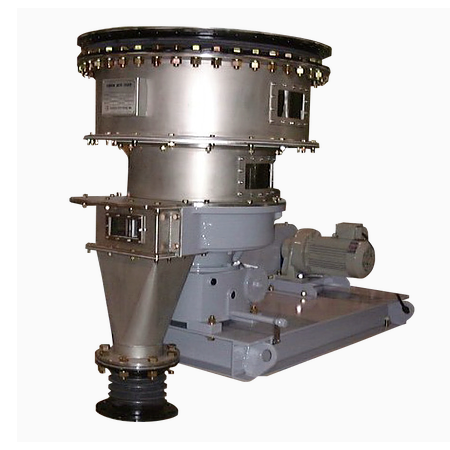

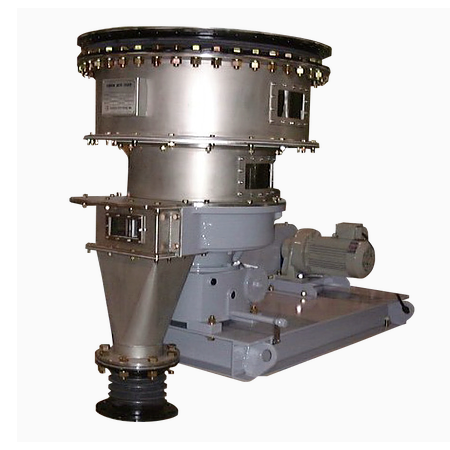

FUNKEN AUTO FEEDER (FI model)

For high fluidity powders

The FI model feeder is an accurate and reliable feeder which enables accurate feeding of powders with high fluidity easy to flush like fine coals.

DOWNLOAD

CATALOGUE

Product features

- A special flexible structure seal is developed for preventing abrasive wearing of the metal face and feeding fluctuation due to temperature change.

- There is no invasion of powder into the inside of the bearing because it is perfectly sealed.

- There is no leakage and dust generation.

Industries

| Petrochemical |

Chemistry |

Foods |

Civil |

Laboratory |

Environment |

Others |

| ○ |

○ |

○ |

○ |

○ |

○ |

○ |

Model/Capacity

| Model |

Maximum capacity (Lit/h) |

Power (kW) |

| Q |

800 |

0.75 |

| E |

2,500 |

1.5 |

| K |

7,000 |

2.2 |

| R |

20,000 |

3.7 |

| M |

40,000 |

5.5 |

| U |

100,000 |

7.5 |

*Capacity and ratio can differ based on the physics of powder.

*1 Feeding rate accuracy in variation -less than ±0.5-1.0% ( for constant apparent bulk density)

*2 Capacity range is from 1 to 10-20.

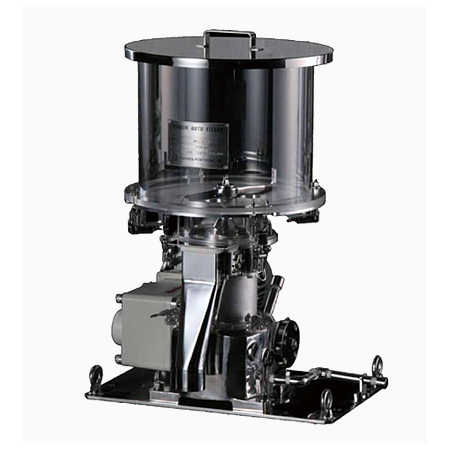

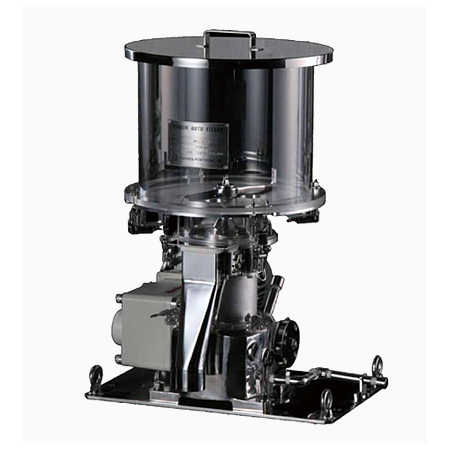

FUNKEN CARTRIDGE FEEDER

Easy to disassemble

The FUNKEN CARTRIDGE FEEDER is developed to make it easy to disassemble and change powder cartridges with a one-touch operation.

DOWNLOAD

CATALOGUE

Product features

-It is good to maintain because of the easy-to-dissemble structure.

-The weight of cartridges is light to handle with 9 kg for SJ model and 11 kg for J model.

There is no need to have more than 1 operator to work with.

Industries

| Petrochemical |

Chemistry |

Foods |

Civil |

Laboratory |

Environment |

Others |

| |

○ |

○ |

|

○ |

|

○ |

Model/Capacity

| Model |

Maximum capacity (Lit/h) |

Cylindrical Container(Lit.) |

Motor (kW) |

Weight(kg) |

| SJ |

30 |

15 |

0.2 |

35 |

| J |

200 |

15 |

0.4 |

40 |

*Capacity and ratio can differ based on the physics of powder.

*1 Feeding rate accuracy in variation -less than ±1.0% as instant value, ±5% as accumulated value ( for constant apparent bulk density)

FUNKEN BIT FEEDER

For micro amount powders

The FUNKEN BIT FEEDER is developed to feed micro amounts of powders with accuracy in a continuous process. It is small but the basic design concept is common with other feeders.

Product features

-There is no need to use tools to dissemble, clean or change powders.

-Suitable for laboratories and schools as an experimental device.

- Highly evaluated as the feeder for micro amount grinder.

Industries

| Petrochemical |

Chemistry |

Foods |

Civil |

Laboratory |

Environment |

Others |

| |

|

|

|

○ |

○ |

○ |

Model/Capacity

| Model |

capacity(cc/h) |

| B1 |

50 ~ 500 |

| B2 |

100 ~ 1000 |

| B3 |

300 ~ 3000 |

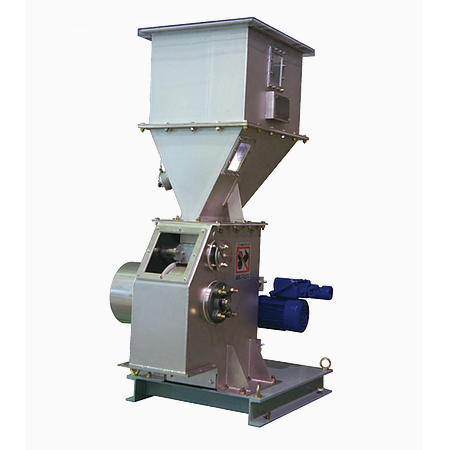

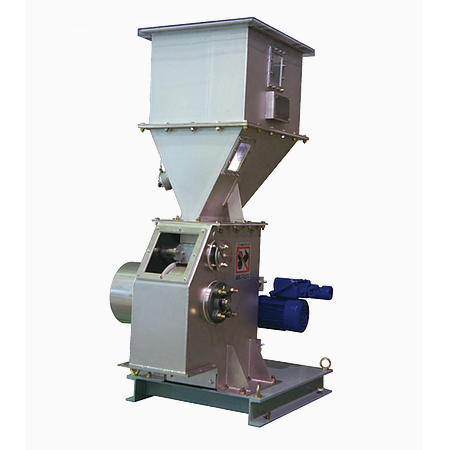

FUNKEN ROLL FEEDER

For pellets and granular materials

The FUNKEN ROLL FEEDER was developed for feeding granular/pellet materials. The contact surface of the feed roller is specifically processed to protect supplying material. Its simple design uses a semi-round gate to adjust the feed rate.

DOWNLOAD

CATALOGUE

Product features

-It is suitable to feed delicate materials to keep the surface intact.

-Easy to adjust feeding rate with accuracy by changing openness of discharge gate or the rotation speed.

- It is hard to get out of order because of the simple structure.

- Easy to discharge all the supply material and the inside cleaning is stress-free.

Industries

| Petrochemical |

Chemistry |

Foods |

Civil |

Laboratory |

Environment |

Others |

| ○ |

○ |

○ |

○ |

○ |

○ |

○ |

Model/Capacity

| Model |

Maximum capacity (Lit./h) |

Power (kW) |

| FRG-35 |

900 |

0.2 |

| FRG-65 |

1,700 |

0.2 |

| FRG-125 |

3,300 |

0.2 |

| FRG-250 |

6,600 |

0.2 |

| FRG-500 |

13,200 |

0.4 |

| FRG-503 |

23,000 |

0.4 |

*Capacity and ratio can differ based on the physics of powder.

*1 Feeding rate accuracy in variation -less than ±0.5-1.0% ( for constant apparent bulk density)

*2 Capacity range is from 1 to 10-20.

FUNKEN PNEUMA FEEDER

For pneumatic transportation of powders

The FUNKEN PNEUMA FEEDER is developed to feed powder directly into the pneumatic transportation pipes without an airlock.

DOWNLOAD

CATALOGUE

Product features

-There is no need to have an airlock because of the optimized clearance of the inside feeder and the sealing mechanism of the supply material itself (material seal).

-Adhesive powders can be discharged completely by blowing air at the discharging part.

-It is easy to coordinate the horizontal direction of discharging.

-There is optional design for multiple discharging gates.

Industries

| Petrochemical |

Chemistry |

Foods |

Civil |

Laboratory |

Environment |

Others |

| |

○ |

○ |

○ |

○ |

○ |

○ |

Model/Capacity

| Model |

Maximum capacity (Lit./h) |

Cylindrical Container (Lit.)

One-way type |

Motor (kW) |

Air Consumption(1)

(NLit./min) |

Air Consumption(2)

(NLit./min) |

| One-way type |

One-way Multi-way |

| S |

1 |

75 |

9.5 |

0.2 |

0.2 |

30 |

2.2〜3.5 |

| 2 |

150 |

| J |

1 |

300 |

9.5 |

0.2 |

0.2 |

30 |

3.5〜8.0 |

| 2 |

600 |

| Q |

1 |

1,200 |

22.5 |

0.4 |

0.4 |

50 |

8.0〜25 |

| 2 |

2,400 |

*1Please contact us to select the right model for your inquiry. The required feeding rate capacity is different depending on the physics of your supply material.

*2 Air consumption (1) refers to dry air for impeller blowing and (2) refers to the pneumatic transportation of powder. The latter number is for reference. It can be variable due to the transportation distance and mixing ration.

*3 The air consumption for multi-direction type is the table value times number of discharge gates.