Our mixing process refers to continuous mixing, and it is different from batch to batch mixing (like in lot orders). In other words, powder is mixed in a non-stop process wihile it is flowing down inside the mixer. We have two kinds of mixers which are the FLOW JET MIXER to moisten/knead/solve/emulsify powder and the FUNKEN FLOW MIXER to have a dry mix of various powders.

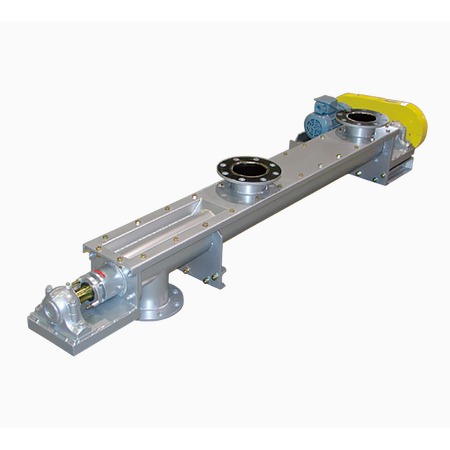

FLOW JET MIXER

For automatic and continuous powder-liquid mixing

The FLOW JET MIXER makes uniformly dispersed powder and liquid mixture instantly. It can achieve moistening/kneading/dissolving of the powder as the mixture flow is down. This was once said to be impossible with conventional mixers before Funken invented it. The accurate feeding of the inlet powder onto the center of the mixer, the high-speed rotation disc’s centrifugal power and the original internal attachments are the keys to success. Our technology makes it happen for you.

DOWNLOAD

CATALOGUE

Product features

-There is no fluctuation in the quality of outlet mixture, and it is uniformly mixed with precise mixing ratio.

-It is hard to get out of order because of the simple structure.

-It is a first-in, first-out mechanism. Therefore, the quality of the outlet mixture is kept stable unlike batch to batch production.

-It is an eco-friendly machine and easy to work with for human operators.

(1) There is no leakage or noise due to the sealed structure.

(2) The motor capacity is small due to the compact design of the machine.

(3) It can achieve a complete automatic operation without operator.

Industries

| Petrochemical |

Chemistry |

Foods |

Civil |

Laboratory |

Environment |

Others |

| ○ |

○ |

○ |

○ |

○ |

○ |

○ |

Model/Capacity

| Model |

Moistening |

Kneading |

Dissolution |

| Capacity (Kg/h) |

Motor (KW) |

Capacity (Kg/h) |

Motor (KW) |

Capacity (l/h) |

Motor (KW) |

| 200 |

100 - 350 |

1.5 - 2.2 |

100 - 350 |

2.2 - 3.7 |

100 - 700 |

0.75 - 1.5 |

| 300 |

300 - 1,000 |

2.2 - 3.7 |

300 - 1,000 |

3.7 - 5.5 |

300 - 2,000 |

1.5 - 3.7 |

| 450 |

500 - 2,500 |

3.7 - 5.5 |

500 - 2,500 |

5.5 - 11 |

1,000 - 5,000 |

3.7 - 5.5 |

| 600 |

1,000 - 5,000 |

5.5 - 11 |

1,000 - 5,000 |

11 - 22 |

2,000 - 10,000 |

5.5 - 7.5 |

| 750 |

2,000 - 10,000 |

11 - 15 |

2,000 - 10,000 |

22 - 55 |

4,000 - 20,000 |

7.5 - 11 |

| 900 |

3,000 - 15,000 |

15 - 22 |

3,000 - 15,000 |

30 - 75 |

6,000 - 30,000 |

11 - 15 |

| 1050 |

4,500 - 22,000 |

22 - 37 |

4,500 - 22,000 |

45 - 110 |

9,000 - 44,000 |

15 - 22 |

*1 Please tell us about what substances to mix, these numbers can differ from physical properties of them and operating conditions.

*2 We have a demonstration machine for experiments in our laboratory.

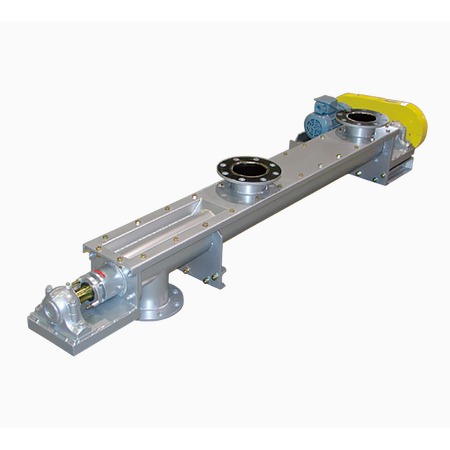

FUNKEN FLOW MIXER

For automatic and continuous mixing for dry powders

The FUNKEN FLOW MIXER is the screw conveyor with powder inlets and mixing part for powders and granules. The customer can build a reliable conveying system and mixing system at the same time when it is combined with the FUNKEN AUTO FEEDER which is an accurate and stable feeder for powder and granule materials.

DOWNLOAD

CATALOGUE

Product features

-It is a horizontal continuous mixer which consists of a transport zone and a mixing zone.

-There is no leakage due to the sealed mechanism.

-While transporting several powders, they can be mixed uniformly and continuously.

Industries

| Petrochemical |

Chemistry |

Foods |

Civil |

Laboratory |

Environment |

Others |

| ○ |

○ |

○ |

○ |

○ |

○ |

○ |

Model/Capacity

| Diameter(screw) |

Capacity (m3/h) |

Motor (kW) |

| 4 (100mm) |

1.5 |

0.4 – 0.75 |

| 8 (200mm) |

9.0 |

1.5 – 2.2 |

| 12 (315mm) |

31.0 |

3.7 – 5.5 |

| 16 (400mm) |

48.0 |

5.5 – 7.5 |

| 20 (500mm) |

74.0 |

7.5 – 11 |

| 25 (630mm) |

115 |

11 – 15 |