Funken has developed an original PID control system with control panels to operate feeders with load cells that have an accurate and flexible control of feeding rates. There are DC-type and DD-type. Please check our product page for further details.

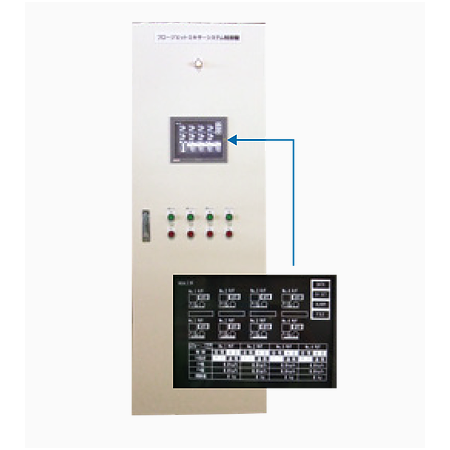

CONTROL PANEL(DC)

For PLC sequencer control

The CONTROL PANEL(DC) is a control device with a quick response and easy maintenance with the PLC sequencer.

Product features

-Quick and stable response.

-Easy to maintain with high reliability due to the general PLC control system.

-It can respond to both continuous processes and batch to batch processes.

-Ratio/synchronizing control are realized comfortably.

-Remote control can be achieved by the separately installed graphics panel.

Industries

| Petrochemical |

Chemistry |

Foods |

Civil |

Laboratory |

Environment |

Others |

| ○ |

○ |

○ |

○ |

○ |

○ |

○ |

General specifications

-Digital input with ten keys on a graphics panel to set the feeding rate.

-Communication and analog signal settings can be selected.

-Set value, feeding rate, accumulated value, apparent bulk density can be displayed.

-Various alarm signals for feeding rate distribution, specific density, HH limit/LL limit etc. can be displayed.

-Outside input/output setting value, feeding rate, apparent bulk density can be converted to analog signal (DC4 mA to 20mA) or communication signal.

CONTROL PANEL(DD)

For microcomputer control

CONTROL PANEL (DD) has a compact design with a microcomputer while the control algorithm is the same as CONTROL PANEL(DC).

Product features

-Printed board is modularized and maintenance is easy.

-Control board can be minimized by a compact controller.

-LCD unit is easy to input by ten flat keys.

-Load cell calibration and span adjustment also can be carried out by ten keys.

-Weight detection is highly accurate by a high-resolution A/D converter.

-They are adaptable to all specifications by parameter setting.

Industries

| Petrochemical |

Chemistry |

Foods |

Civil |

Laboratory |

Environment |

Others |

| ○ |

○ |

○ |

○ |

○ |

○ |

○ |

General specifications

-Digital input with ten keys on graphics panel to set the feeding rate.

-Set value, feeding rate, accumulated value, apparent bulk density can be displayed.

-Various alarm signals for feeding rate distribution, specific density, HH limit/LL limit etc. can be displayed.

-Outside input/output setting value, feeding rate, apparent bulk density can be converted to 4 mA to 20mA for dry contact.